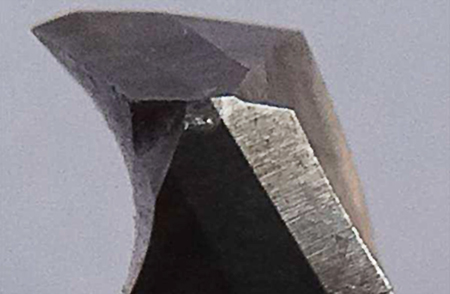

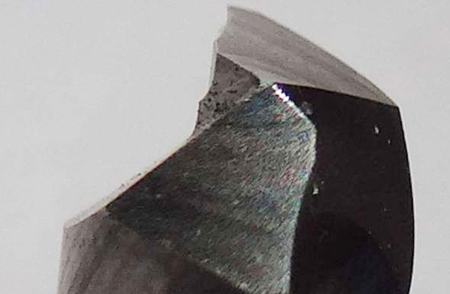

The drill bit is semi-closed cutting, and the heat of drilling is difficult to spread outward, so it is easier to form a high cutting temperature. Therefore, the main cause of bit wear is thermal wear, for high-speed steel bit, mainly phase change wear. In addition, there are contact fatigue, excessive deformation, edge breaking, brittle fracture, cracks, rolled edges and so on.

failure form of drill bit, wear of drill bit, why drill bit will wear, how drill bit wear, wear form of drill bit, mechanical wear of drill bit, thermal wear of drill bit, drill bit grinding, how to grind drill bit, drill bit grinding machine, drill bit grinder

failure form of drill bit, wear of drill bit, why drill bit will wear, how drill bit wear, wear form of drill bit, mechanical wear of drill bit, thermal wear of drill bit, drill bit grinding, how to grind drill bit, drill bit grinding machine, drill bit grinder

Mechanical wear: Workpiece materials contain hard particles with high hardness of tool materials or adhere to debris, which will be scratched on the surface of tool to make tool wear. Mechanical friction and wear are the main causes of tool wear in low speed cutting.

Thermal wear: Thermal wear usually occurs in sliding friction (whether lubricated or not). When the sliding speed is very high (steel to steel, greater than 3~4m/s), and the specific pressure is also very high, a lot of friction heat will be generated to deteriorate lubricating oil, and surface metals will be heated to softening temperature, local metal adhesion occurs at contact points, tearing and breaking off of larger metal particles or even melting. This form of wear is called thermal wear.

Phase change wear: Tool material is worn due to the transformation of Martensitic Structure translate into Troostite on the surface of cutting material and the decrease of hardness. Phase transformation occurs at 550 – 660 ℃ for HSS cutting tools.

Contact fatigue: A phenomenon of surface fatigue spalling damage caused by repeated long-term action of contact pressure stress on the contact surface of parts. The damage is caused by a number of needle-shaped or bean-shaped pits with different depths on the smooth contact surface, or by a large area of crushing of the surface, which is generally referred to as contact fatigue failure.

Excessive Deformation: When the working load and temperature are the elastic deformations produced by the parts exceed the allowable values of the parts matching, the elastic deformation will fail.

Blade breakage: brittle fracture of tool.

Brittle fracture: There is no obvious plastic deformation before fracture.

Broken: refers to the blade larger pieces of ground broken.

Cracks: Tools are damaged by periodic impact or thermal stress, which causes cracks in the teeth.

Winding edge: The plastic deformation of the edge occurs after it is extruded.

When the bit fails, it can be grinded to make the bit used again. How to grind the drill bit? There are many articles on our website about grinding methods, including manual grinding of drills and repairing drills with a drill bit grinder. You are welcome to follow our article http://www.grindervip.com/news/ .