Methods of drilling twist drill and points for attention

Drilling methods:

- Before drilling, the workpiece plane should be leveled. No convex platform is allowed in the center to facilitate the correct centering of the twist drill.

- Align the tailstock so that the center of the twist drill is aligned with the axis of rotation of the workpiece. Otherwise, the diameter of the hole may be larger, the deviation of the drill may even break the twist drill.

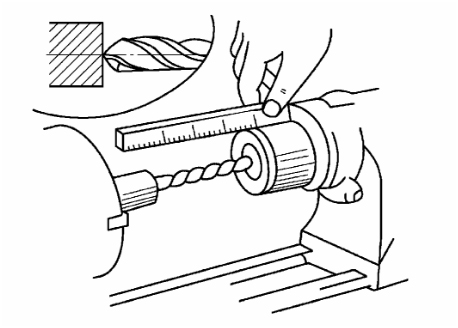

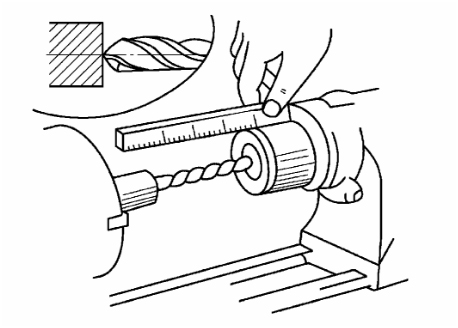

- When drilling with a slender twist drill, in order to prevent the twist drill from shaking, a retaining iron can be clamped on the tool holder to support the head of the twist drill and help the twist drill to determine its center.

- When drilling with a small diameter twist drill, the central hole is drilled on the end face of the workpiece before drilling. In this way, it is convenient to fix the center, and the drilled hole has good coaxiality.

- When drilling holes in solid materials, twist drills can be used to drill once when the aperture is small. If the aperture is large (over 30 mm), it should be drilled twice.

- The method of drilling blind holes is basically the same as that of drilling through holes, but the depth of holes needs to be controlled when drilling. The common control methods are: shaking the tailstock handwheel at the beginning of drilling, measuring the extension length of tailstock sleeve with steel ruler when the cutting part of twist drill cuts into the end face of workpiece, and controlling the extension amount of tailstock sleeve with the length of sleeve extended and the depth of hole when drilling.

drilling methods of twist drilling, drilling methods of twist drilling, drilling methods of blind holes, drilling methods of through holes, points for attention in drilling