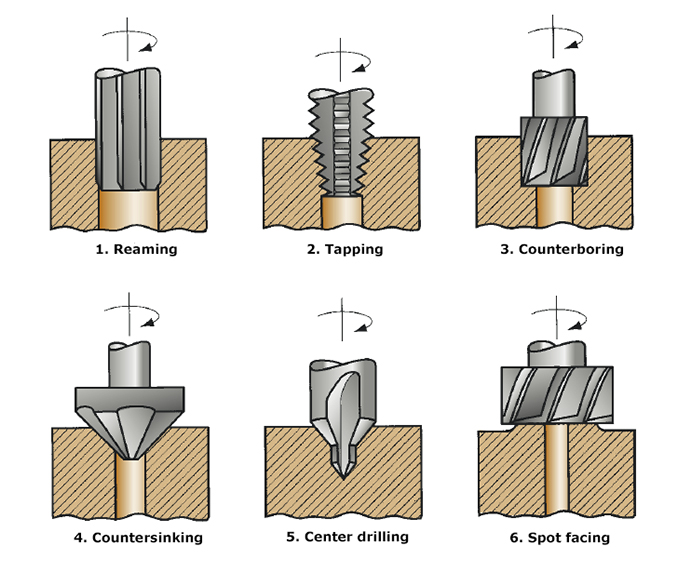

Several operations related to drilling

Hole is an important surface on the box, bracket, sleeve, ring and disk parts, and is often encountered in machining. Drilling refers to the method of machining holes on solid materials with drill bits. There are several operations related to drilling. Some of them are:

- Reaming,

- Tapping,

- Counterboring,

- Countersinking,

- Center drilling,

- Spot facing

These are shown in the diagram and described in this section. Most operations follow the drilling process; a hole must be drilled first and then modified by other drilling operations. Centering and spot facing operations are exceptions to this rule. All of the operations use rotating tools.

1. reaming, 2. tapping, 3. counterboring, 4. countersinking, 5. center drilling, and 6. spot facing Figure 1: Machining operations related to drilling

- Reaming:The reaming operation is used to expand the hole slightly, so that its diameter is better tolerated and the surface finish is improved. The tool is called a reamer, and it usually has straight flutes.

- Tapping:The tapping operation is performed by taps and is used to provide internal threads on existing holes.

- Counterboring:The counterboring operation provides a stepped hole, where the larger diameter follows the smaller diameter part into the hole. A counterbored hole is used to fix the bolt head in a hole, so the head does not protrude above the surface.

- Countersinking:countersinking operation is similar to counterboring, except that the step in the hole is cone-shaped for flat head screws and bolts.

- Centering:centering operation also called center drilling, this operation drills a starting hole to establish its location for subsequent drilling accurately. The tool is known as a center drill.

- Spot facing:spot facing operation is similar to milling. The operation is used to provide flat machined surfaces on workpieces in local areas.

Technical requirements for drilling

Size accuracy: aperture and length of the dimensional accuracy.

(2) shape accuracy: hole roundness, cylindricity and axis straightness.

(3) accuracy of position: hole and hole or hole and the concentricity of the circular surface, hole and hole or hole and other surfaces between the dimensional accuracy, parallelism, perpendicularity and so on.

(4) the quality of the surface: surface roughness, surface machining hardening and surface physical and mechanical properties requirements.

Universal Tool Grinder, Universal Cutter Grinder, Drill Bit Grinder, End Mill Grinder, Complex Grinder for Drill and Mill, Screw Tap Grinder, Lathe Tool Grinder, Saw Blade Grinder, Belt Sander, Grinder Attachment, Grinding Wheel

In drilling operations, if your drill bit has some small cracks, you can use our drill bit grinding tools (drill bit grinding machines) to repair and reuse.